Our Technology

At Pazzi, we combine the latest in CNC machine technology with traditional methods of hand-working and finishing stone. Our fully automatic equipment allows us to process safely, efficiently and with great precision.

Pazzi’s suit of equipment include:

Two Italian-made CNC machines – the Denver Unika 5 HT (a five-axis CNC high-tech work centre).

The Prussiani dual table – a workhorse that features a five-axis CNC high-capacity saw and water jet.

Denver Unika 5 HT

CNC high tech work centre is equipped with a powerful ISO40 electro spindle, versatile 3D software and automated tool change with 26 cutting, shaping, engraving and polishing tool heads enables us to quickly adapt the machines abilities to “realise your design in stone” precisely with varying degrees of complexity.

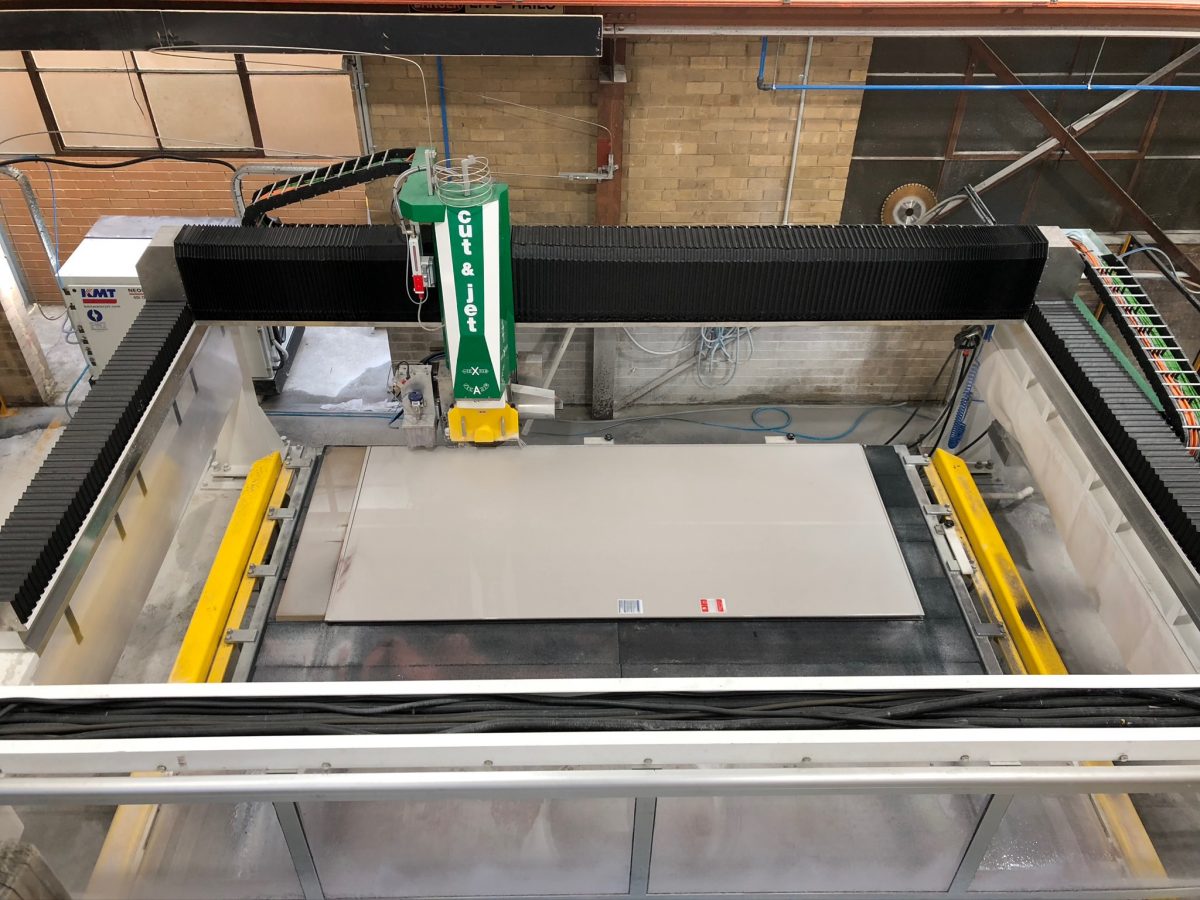

Prussiani

This Machine is a dual shuttle table with a five-axis CNC saw and water jet. It is an advanced and powerful cutting machine, the dual shuttle table makes it possible for a continuous flow of work, loading slabs and unloading cut parts safely.

The combination of having a saw and water jet on the same cutting head provides for a remarkable versatility it is possible to create even the finest details – such as curves, intricate kitchen benchtops, luxurious bathrooms vanities, high-end floor and wall panels, inlays, lettering and logos and more.

The two machines are able to cut and shape all types of natural and engineered stone, as well as ultra-compact materials. This includes any types of marble, granite, travertine, onyx, porcelain and engineered varieties. Before processing the material, our team utilises a dedicated photo station equipped with a green screen, backed by powerful rendering software to provide a “vein matching service”. This allows us to nest the parts of your job onto the selected slabs, ensuring that the most desired parts of the material are used, achieving perfect pattern flow.

This technology, coupled with the traditional handcraft of working stone, gives us the ability to go that extra step for our customers. From cutting fine lettering to forming perfect outstanding bench tops – we always make sure our customers consistently get the best possible product they can.